Copy, Print and Delivery Services celebrates In-Plant Awareness Month by showcasing its accomplishments over the past year and offering an example of the steps involved in completing a project.

The In-Plant Printing and Mailing Association (IPMA) created the event to recognize the dedicated in-house design, printing, mailing, and distribution teams and to introduce the public to the complexity and precision of the industry during February.

2025 Highlights

In 2025, In-Plant Impressions magazine ranked the UH facility, with its 23 employees, 48th on the list of the largest in-plants in North America, and 54th with fiscal-year sales of $2,427,576. The team completed 2,837 projects throughout the calendar year and earned a platinum production and impression award from the Association of College and University Printers (ACUP+) for their Report on Philanthropy brochure that detailed the University’s philanthropic efforts.

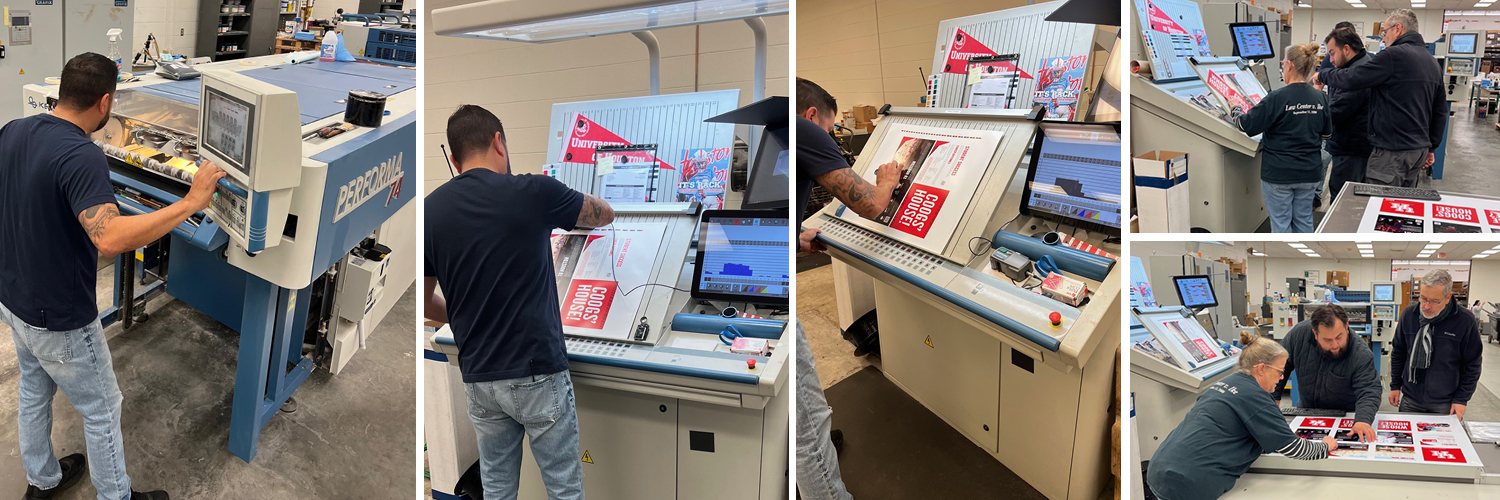

CPD Team in Action

The Admissions department submitted an offset press job that called for 2,000 12-page Undergraduate Admissions brochures that were eight inches by eight inches. The project used 80-pound gloss cover and required design assistance, offset printing, trimming, scoring, folding, and saddle stitching.

The graphic designers received PDF files from Admissions, and set to work on editing, checking color, laying out, and formatting the project.

“We are here to help,” said Eric Dowding, manager, Graphics and Communications. “It’s best to contact us at the beginning of your project to ensure that what is being designed is in the correct format — press ready — and that the correct type of paper is being used.”

Once all the approvals were made, the project was sent to the plating area, where

the layout was reviewed again before the images were laser burned to a plate.

Once all the approvals were made, the project was sent to the plating area, where

the layout was reviewed again before the images were laser burned to a plate.

“I look at the colors and the placement of everything to make sure it is set up correctly and everything that is needed to print is there,” said Sami Snelling, production manager. “Then I make a mock-up to make sure the pages are in the right order.”

For this project, four Fujifilm computer-to-plate plates were needed for production:

One for the front and back covers, one for the covers’ inside pages, and two — with

their images head to toe — for the inside pages. The plates were then sent to the offset press area, where the plates were bent to

fit the press and checked. The press was calibrated, the plates were put into position,

and a few more adjustments were made as proofs were being printed. Proofs were randomly

reviewed to check for quality.

The plates were then sent to the offset press area, where the plates were bent to

fit the press and checked. The press was calibrated, the plates were put into position,

and a few more adjustments were made as proofs were being printed. Proofs were randomly

reviewed to check for quality.

“I make sure the colors and quality stay consistent to produce a good product for

the customer,” said Juan Lozoya, offset press operator 3. “Every job is different.

For every makeready and run, I have to approach it as a totally different project.

It keeps me on my toes.”

“I make sure the colors and quality stay consistent to produce a good product for

the customer,” said Juan Lozoya, offset press operator 3. “Every job is different.

For every makeready and run, I have to approach it as a totally different project.

It keeps me on my toes.”

A press check was made by Administration using a proof that met all the print specifications

for a final approval, which allowed the press to begin its first run on the inside

pages. Once completed, the paper was turned over to print the other side of the page.

This had to be done three times under the watchful eye of Lozoya.

A press check was made by Administration using a proof that met all the print specifications

for a final approval, which allowed the press to begin its first run on the inside

pages. Once completed, the paper was turned over to print the other side of the page.

This had to be done three times under the watchful eye of Lozoya.

The finished print job was then sent over to bindery, where it was cut into sections

at the cutter. Measurements were taken before making the cut to ensure the machine

is set correctly. The operator also used a pedal to manually view where the blade

was going to fall before pressing the button to make the cut. Cut mock-ups were made

for each section to ensure the pages aligned correctly.

The finished print job was then sent over to bindery, where it was cut into sections

at the cutter. Measurements were taken before making the cut to ensure the machine

is set correctly. The operator also used a pedal to manually view where the blade

was going to fall before pressing the button to make the cut. Cut mock-ups were made

for each section to ensure the pages aligned correctly.

The cut sections then went to the folding machine to be folded and examined to check

on the completed folds. From there, the cover and the inside sections were placed

on their designated locations on the saddle stitch machine, where they were grouped,

stapled, and trimmed. After the machine was calibrated, the process began. It had

to be closely watched due to the chance of paper misalignment, jams, belt failure,

faulty stitching wire, or trim scraps blocking the chute.

The cut sections then went to the folding machine to be folded and examined to check

on the completed folds. From there, the cover and the inside sections were placed

on their designated locations on the saddle stitch machine, where they were grouped,

stapled, and trimmed. After the machine was calibrated, the process began. It had

to be closely watched due to the chance of paper misalignment, jams, belt failure,

faulty stitching wire, or trim scraps blocking the chute.

“You have to keep a constant eye on everything with this machine,” said Salvador Bautista,

bindery operator. “And if something should occur, you have to bird dog it!”

“You have to keep a constant eye on everything with this machine,” said Salvador Bautista,

bindery operator. “And if something should occur, you have to bird dog it!”

Finished brochures were randomly checked for proper page alignment — especially where

an image continued on a separate folded page — and that the stapling was consistent

before being boxed.

Finished brochures were randomly checked for proper page alignment — especially where

an image continued on a separate folded page — and that the stapling was consistent

before being boxed.

“Our production staff brings more than 150 years of combined experience to every project,” said Snelling. “As the final team to review each job before it reaches the customer, we take pride in delivering the highest-quality work — work that represents our standards and is seen across the entire University campus.”

Visit Copy, Print and Delivery Services online to learn more about UH’s in-plant printing operations. Contact the team for your next printing project, or to schedule a tour of the facility.